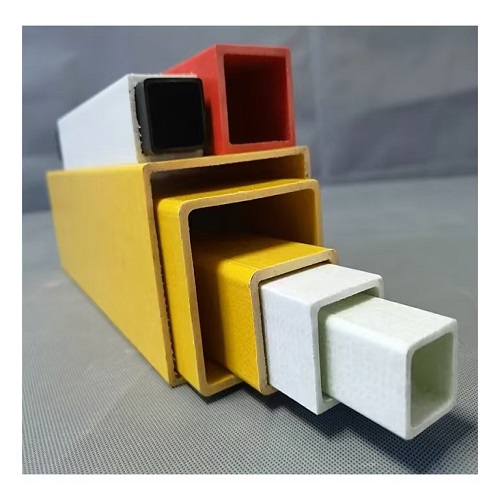

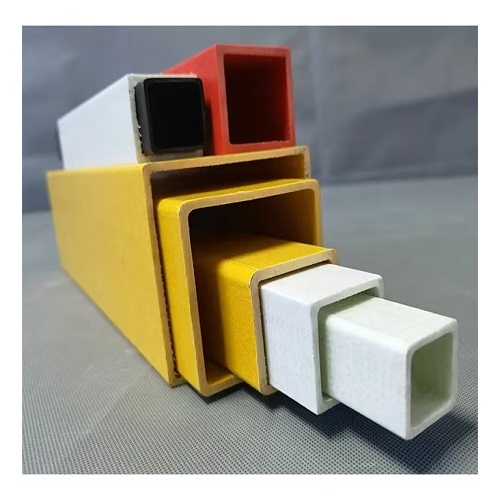

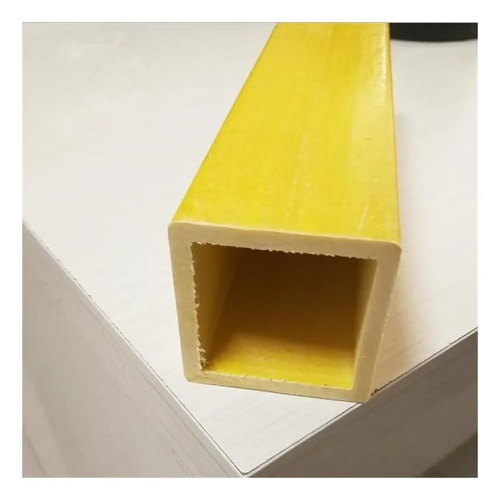

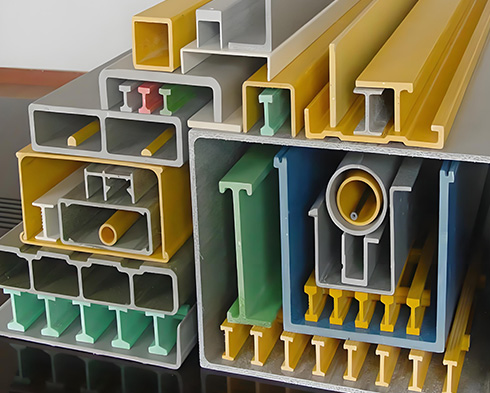

Description details of fiberglass square tube:

characteristic

1. Lightweight and High Strength: It weighs only 1/4 to 1/5 of steel, but has similar strength to steel, which can reduce the support structure and overall weight.

2. Corrosion resistance: It has good resistance to atmosphere, water, acid, alkali, salt, oil, and solvents, and is suitable for corrosive environments.

3. Good weather resistance: It can maintain good performance and appearance in natural environments such as ultraviolet radiation, moisture, ice and snow, freezing and thawing.

4. Easy to process and install: It can be cut, bent, connected, etc., making installation simple and reducing construction costs.

5. Environmental protection and energy conservation: No harmful substances are produced during production and use, which can reduce the weight of the structure and lower energy consumption.

6. Electrical insulation: It has good electrical insulation performance and can be used as an insulation bracket for power equipment.

7. Small coefficient of thermal expansion: The coefficient of thermal expansion is close to that of steel, much smaller than plastic materials, and has outstanding dimensional stability.

8. Good wear resistance: The degree of wear on the pipe wall is low, making it suitable for scenarios such as highway and bridge construction.

9. Outstanding frost resistance: In an environment of minus 40 degrees Celsius, the liquid inside the pipeline will not freeze and crack even if it freezes.

10. Heat and high temperature resistance: It will not soften or deform at ambient temperatures up to 150 degrees Celsius, and can be used as a good insulation material.

11. Long service life: The normal service life can reach more than 20 years, with low transportation and installation costs and high cost-effectiveness.

application area

Construction industry: used for doors, windows, partitions, ceilings, exterior wall decoration, etc., to make buildings more beautiful, energy-efficient, and environmentally friendly.

Transportation: Used as supporting and connecting components for vehicles, ships, bridges, and other structures to maintain good performance in harsh environments.

Environmental engineering: used as supporting and covering materials for facilities such as sewage treatment, exhaust gas treatment, and landfill, ensuring safety and reliability.

Electric power industry: used as cable trays, cable protection pipes, etc., to protect cables, with good insulation performance and corrosion resistance.

Other fields: such as petroleum, chemical, metallurgy, urban water supply and drainage, gas transportation, geothermal engineering, etc.